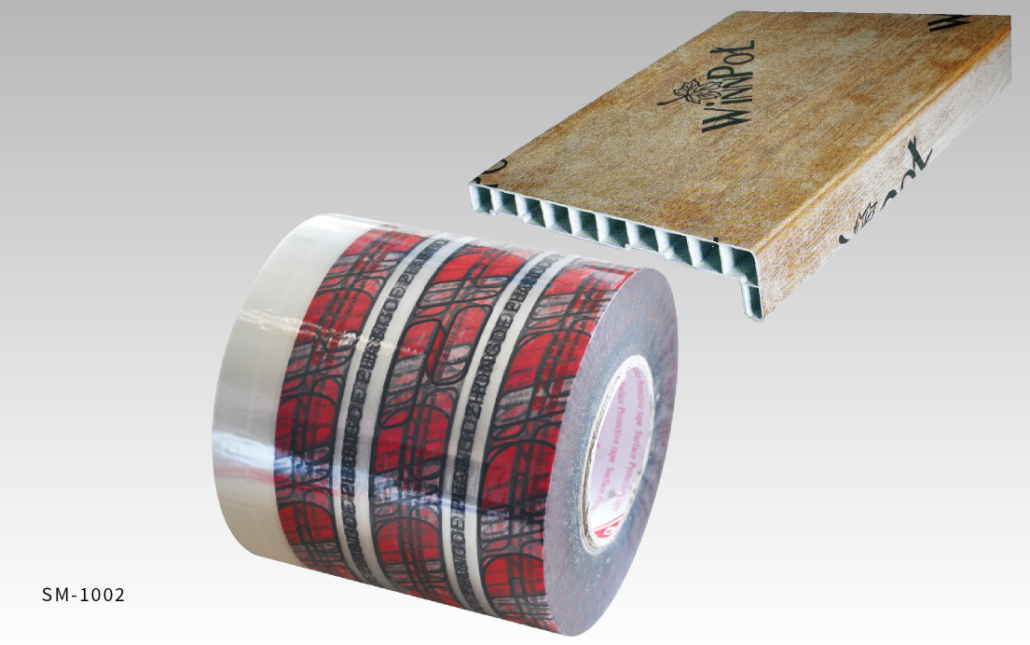

Uses and Applications of Aluminum Profile Protective Film

Aluminum profile protective film finds wide-ranging applications in various fields such as construction, decoration, furniture, and electronics, providing significant benefits and value:

1. Construction Industry:

– Aluminum profiles are extensively used in construction for window frames, door frames, curtain walls, roofs, and facades. Protective films safeguard the aluminum surface from scratches, contamination, and damage during manufacturing, transportation, and installation. They ensure that aluminum profiles maintain their appearance and performance throughout their service life, thus extending their lifespan.

2. Decoration:

– Aluminum profiles are commonly employed for indoor and outdoor decorative applications like wall panels, ceilings, partitions, and stair handrails. Protective films shield the aluminum surface against scratches, fingerprints, paint splatters, and daily wear and tear. They preserve the smooth, glossy, and clean appearance of aluminum profiles, enhancing the overall decorative effect.

3. Furniture Manufacturing:

– Aluminum profiles are widely used in furniture manufacturing, including tables, chairs, cabinets, and display shelves. Protective films protect the aluminum surface from scratches, fingerprints, and stains, ensuring the visual quality of the furniture. Additionally, these films can provide UV resistance, preventing fading of the furniture surface due to prolonged exposure to sunlight.

4. Electronics:

– Aluminum profiles are commonly utilized in electronic product manufacturing for casings, heat sinks, and brackets for electronic components. Protective films shield the aluminum surface from scratches, chemical corrosion, and electrostatic damage. They ensure the integrity of the electronic products’ appearance and stability, improving product reliability and durability.

The significance and value of aluminum profile protective films can be summarized as follows:

1. Surface Protection: The protective film forms a layer of protection, guarding the aluminum surface against physical damage, chemical corrosion, and contamination, thus preserving its appearance and performance.

2. Extended Service Life: Protective films prolong the lifespan of aluminum profiles by reducing the frequency of repairs and replacements, thereby lowering maintenance costs.

3. Enhanced Aesthetics: Protective films maintain the smooth, glossy, and clean appearance of aluminum profiles, enhancing the visual quality and decorative effect of products.

4. Increased Value: By safeguarding the appearance and performance of aluminum profiles, protective films enhance the quality and value of products, thereby improving their competitiveness in the market.

In conclusion, aluminum profile protective films have extensive applications in the construction, decoration, furniture, and electronics industries, providing essential protection and value for aluminum profiles. By selecting suitable film types and materials, their effectiveness can be maximized to protect aluminum profiles while enhancing product quality and sustainability.

Leave a Reply

Want to join the discussion?Feel free to contribute!