Color and Texture Selection of Aluminum Profile Protective Films

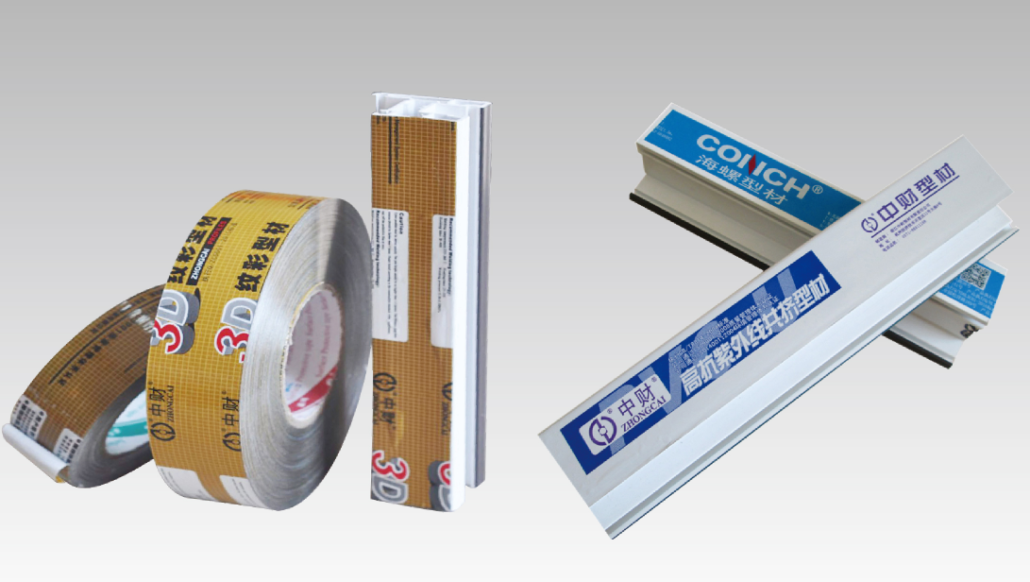

Aluminum profile protective films offer a variety of color, pattern, and texture options to meet the diverse needs of different users. Here is a discussion of these options and how to choose the most suitable protective film based on requirements:

1. Color Selection:

– Transparent/Clear: Transparent or clear protective films provide the most natural appearance without altering the look and color of the aluminum profile.

– Colored: Protective films also come in various color options such as black, white, silver, blue, etc. These colored films can enhance the visual appeal of the product or match specific design requirements.

2. Pattern and Texture Selection:

– Smooth: Smooth protective films are typically used to provide basic protection without any specific patterns or textures.

– Fine Patterns/Lines: Some protective films may feature fine patterns or lines to add surface texture and decorative effects to the aluminum profile.

– Custom Patterns: Protective film manufacturers can also offer custom patterns and textures to meet specific design requirements of users.

Choosing the most suitable protective film depends on the following factors:

– Aesthetic requirements: Choose transparent or colored protective films based on the overall appearance and design requirements of the product. Transparent films showcase the original appearance of the aluminum profile, while colored films enhance visual appeal.

– Surface requirements: Consider the surface characteristics and needs of the aluminum profile. Smooth protective films provide basic protection, while films with textures and patterns can enhance decorative effects or match specific design requirements.

– Application environment: Select a suitable protective film based on the application environment of the aluminum profile. For example, if the profile will be exposed to harsh weather conditions or high wear environments, choosing a film with higher durability and resistance to wear may be more appropriate.

Additionally, communicating with protective film manufacturers and understanding their product lines and customization options is crucial in choosing the most suitable protective film. Manufacturers can provide customized color, pattern, and texture options based on specific user requirements to ensure the protective film aligns with the overall design and requirements of the product.

In summary, choosing the most suitable protective film for aluminum profiles can be achieved by considering color, pattern, and texture options based on aesthetic requirements, surface needs, and application environment. Communicating with manufacturers and understanding their product lines and customization options are key to selecting the best protective film.

Leave a Reply

Want to join the discussion?Feel free to contribute!