Applications of PVC Protective Film

PVC protective film finds extensive applications in various fields such as construction, furniture, automotive, and electronics. Its roles and values may vary slightly across different industries.

1. Construction Industry:

– Protection of building profiles: PVC protective film is used to safeguard architectural elements like door and window frames, wall panels, ceilings, and wall guards from scratches, contamination, or damage during construction. They provide temporary protection, ensuring that building materials maintain a good appearance and quality during transportation, installation, and renovation.

– Decoration and surface treatment: PVC protective film is also employed for decoration and surface treatment, offering different colors, textures, and appearances to buildings. They can mimic wood grain, metallic patterns, or stone textures, enhancing the aesthetic appeal of the structures.

2. Furniture Industry:

– Surface protection of furniture: PVC protective film is widely used in furniture manufacturing to shield furniture surfaces from scratches, wear and tear, contamination, and daily usage. They can cover tabletops, chair backs, furniture edges, providing durable protection while maintaining the fresh appearance of the furniture.

– Enhancement of aesthetics: PVC protective film can also enhance the visual appeal and design of furniture. By selecting protective films with different colors, patterns, and textures, furniture can be given a personalized appearance, catering to the preferences of various consumers.

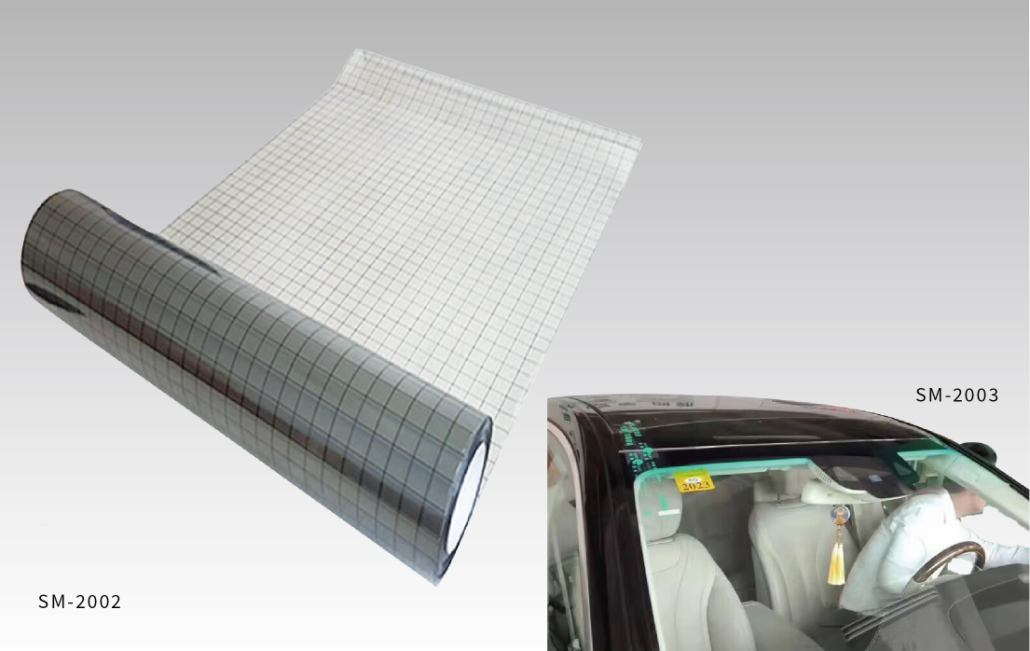

3. Automotive Industry:

– Surface protection: In the automotive manufacturing process, PVC protective film can be applied to protect the surfaces of car bodies, doors, window frames, and other exterior components. They prevent scratches, contamination, and damages that may occur during transportation, storage, and assembly, thus maintaining the visual quality of the vehicles.

– Decoration and branding: PVC protective film can be used for automotive decoration and branding. They can cover body parts, providing specific colors, patterns, and logos to meet the requirements of automotive manufacturers and consumers.

4. Electronics Industry:

– Protection of electronic products: PVC protective film is utilized in the electronics industry to safeguard the surfaces of electronic devices. For example, smartphones, tablets, TV screens, and other products can be covered with protective films featuring scratch resistance, stain resistance, and anti-fingerprint properties, thus extending their lifespan and maintaining high-definition clarity and touch sensitivity.

– Insulation and encapsulation: PVC protective film can also be used for insulation and encapsulation of electronic components. They can form protective layers on circuit boards, preventing dust, moisture, and other external environmental factors from affecting electronic components.

In conclusion, PVC protective film has a wide range of applications in the construction, furniture, automotive, and electronics industries. They provide temporary or long-term protection, safeguarding items from damage and contamination, while adding aesthetic appeal and design features to products. By utilizing PVC protective films, these industries can enhance product quality, prolong lifespan, and meet consumers’ expectations regarding quality and appearance.

Leave a Reply

Want to join the discussion?Feel free to contribute!