Basic knowledge of BOPP film

BOPP is the abbreviation of BiaxiallyOriendPolypropylene, film is two-way stretch polypropylene film film is a kind of very important soft packing material, film colorless, odorless, tasteless, non-toxic, and has a high tensile strength, impact strength, rigidity, strong toughness and good transparency.

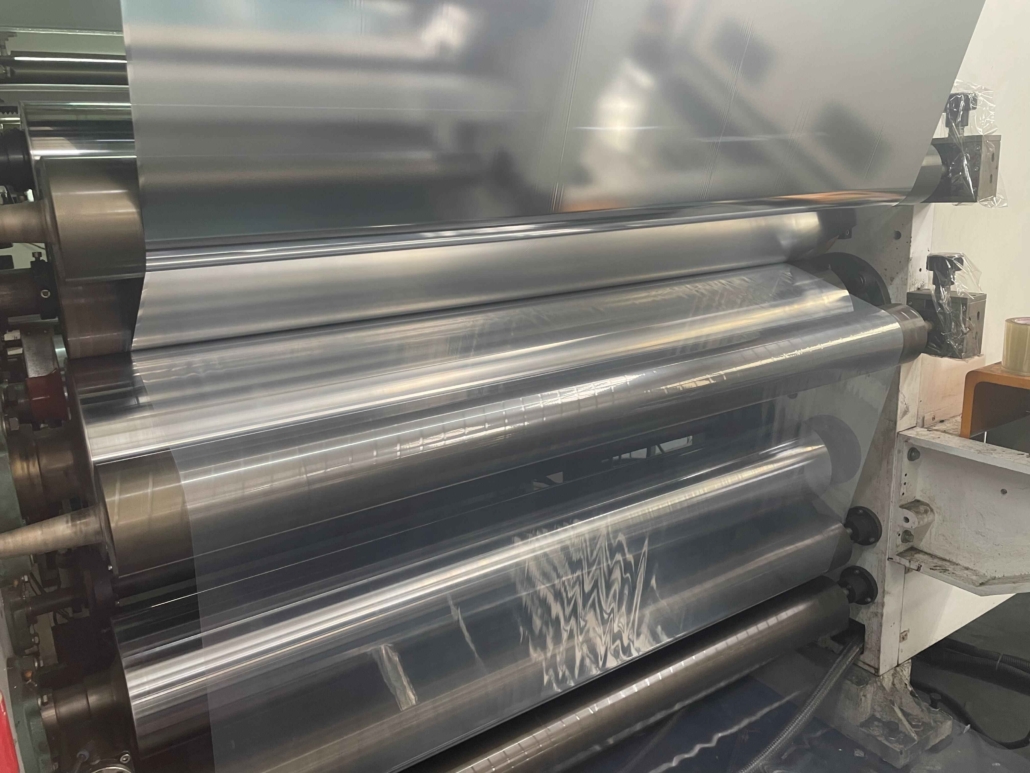

BOPP film production is the polymer polypropylene melt first through the long and narrow head into sheet or thick film, and then in the special stretching machine, at a certain temperature and set speed, at the same time or distribution in the vertical of the two reverse (vertical, horizontal) tensile, And after appropriate cooling or heat treatment or special processing (such as corona, coating, etc.) made of film.

BOPP classification and application, according to the use can be divided into:

Ordinary type: also known as light film, flat mold. For printing, composite (transparency, extinction type), coating (adhesive tape and PVDC coated film base film). It is the most widely used film products, the largest production variety: printing film, composite film, tape film, bag film, extinction film, etc., are flat film.

Heat sealing type: used for ordinary packaging, such as cigarette packaging film, three layers of heat sealing film, five layers of air blocking film, pearlescent film, coated heat sealing film, etc. : heat sealing film, laser film, belongs to the heat sealing film.

Label film: for commodity labels, advertising printing, written magazines, bottle labels and overall packaging, etc. : Metallized film: for vacuum aluminum plating: capacitor film: for capacitors and metal capacitors.

Subdivision of membrane types:

BOPP ordinary film, also known as light film, is suitable for food packaging, paper composite and general packaging printing composite, is the largest amount of BOPP products. Flat film, also known as light film, is bidirectional tensile polypropylene film (BOPP film) series of products in one of the most common film, is widely used in all kinds of printing, composite products for a variety of food, goods packaging. Among them, the 15dm thickness of the flat film is mainly used for books and other paper composite.

In the consumption of light film, plastic bag film occupies a large proportion, quite a few film factories will be the tape film as the main product. The production of belt film has such characteristics as large yield, simple process and low technical requirements.

Although the overall use of smoke film matte film is not big, it is the most profitable products in BOPP film. The characteristics of cigarette film production and sales, high technical requirements, large entry cost.

Matte (matte) film

Matting film is a kind of plastic matting product with low gloss (glossiness less than 15) and high fog into diffuse matting effect. It has the characteristics of paper-like appearance, realistic reproduction of color in printing and comfortable feel. Matting film is a film made by bidirectional stretching of matting master material on a single surface. The surface of the matting film looks like paper and natural products. It is mainly used for the composite of books, time-penalty, annual report covers, cardstock and other papers. Another use is to cooperate with polyethylene film, casting polypropylene film, BOPP film, pearlizing film, metallized film and other packaging.

Single and double sided heat sealing film

The heat-sealing film is divided into two kinds of single-side heat-sealing film box two-way heat-sealing film. It is a polypropylene heat-sealing film (BOPP heat-sealing film) made of heat-sealing master material on the surface. It is mainly used to experience the heat-sealing packaging of food, medicine and other electrical components. It is divided into two kinds: single-side hot sealing and double-side hot sealing. Single-side hot sealing film is used for general purpose single-side hot sealing packaging. It is cheap and printable. Mainly used for compound, printing, bag making and so on.

Pearlescent film

White opaque BOPP pearlescent film has a silky texture, soft and pleasant pearl luster, low density, excellent flatness, gas barrier, can be widely used in dried fruit, ice cream, candy, high-end soap, gifts and other direct packaging, at the same time it is a better printing base. In the surface printing can not carry out the full version of the base, therefore, BOPP pearlescent film is highly favored, compared with the ordinary BOPP film, BOPP pearlescent film has three typical characteristics: emit pearlescent luster, good shading, (especially for UV light barrier) and low density. In particular, the first two characteristics show that BOPP pearlescent film is remarkable, so that it enters the high-end market in the field of packaging, bringing considerable economic benefits for manufacturers.

Leave a Reply

Want to join the discussion?Feel free to contribute!