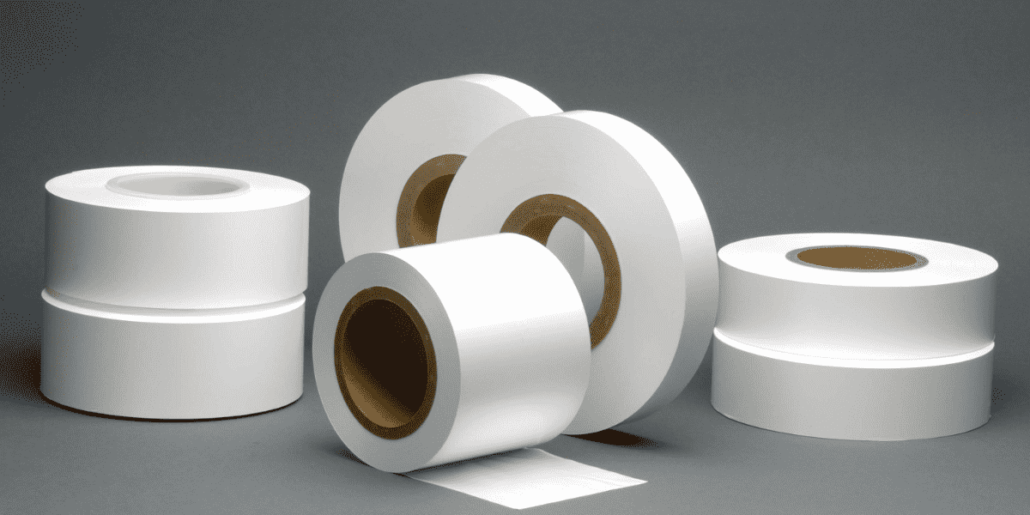

Industrial packaging – BOPP tape

First, the definition of tape

Step 1 Define

Tape is composed of substrate and adhesive two parts, through bonding to make two or more disjointed objects connected together.

The surface is coated with adhesives that originally came from animals and plants. In the 19th century, rubber became the main component of adhesives. Today, a wide variety of polymers are used. Adhesives can stick because their molecules form bonds with the molecules of the object to which they are attached. These bonds hold the molecules together firmly.

Step 2 Sort

(1) According to the base material, it can be divided into BOPP tape, PVC tape, duct tape, kraft tape, American paper tape, fiber tape, PE foam tape, etc.

(2) According to the scope of application, it can be divided into warning tape, carpet tape, electrical tape, protective film paper glue, winding film tape, sealing tape, module tape, etc.

(3) According to the market penetration rate: can be divided into ordinary tape, special tape.

(4) According to the application environment temperature: can be divided into low temperature belt, room temperature belt, high temperature belt.

(5) According to the stickability: single-side tape and double-side tape.

Two, BOPP tape

One,Define

BOPP tape is based on BOPP bidirectional tensile polypropylene film as the base material, after heating evenly coated pressure sensitive adhesive emulsion, so that the formation of 8μm—-28μm adhesive layer, is light industry enterprises, companies, personal life indispensable supplies.

The state has not a perfect standard for the belt industry, only one industry standard “QB/T 2422-1998 BOPP pressure-sensitive adhesive tape for sealing boxes”, the BOPP original film after high voltage corona treatment, one surface formed rough, and then glue coated on it, the first to form a mother roll, and then through the strip machine cut into different sizes of small rolls.

Two,Unit price calculation method

Specifications of BOPP sealing tape are expressed as “width x length x thickness”.

“Width” is the width of the belt, expressed by mm, among which the commonly used specifications are: 50mm, 48mm, 45mm, 40mm, 30mm, etc.;

“Long” refers to the total length of the tape after being pulled apart, which is generally expressed by m or y (1y=0.9144m). Common lengths include 50m, 100m, 200m, 500m, 80Y, 100Y, etc.

“Thickness” refers to the total thickness of BOPP original film + adhesive layer (unit: micron, μm), commonly used 45 ~ 55μm. For example, 50mm x 100m x 50μm.

Calculation method of unit price of each roll of adhesive tape: adhesive tape industry usually uses “yuan/square meter” to calculate the price of adhesive tape, then “price of each roll of adhesive tape = width (m) * length (m) * square price”.

Three, the characteristics of BOPP tape

1. It has strong tensile strength. Due to the directional effect of molecules, crystallinity is improved, tensile strength, impact strength, rigidity, toughness, moisture resistance, transparency are higher, film cold resistance is also higher, can prevent product leakage or damage in transportation.

2. Good printing performance. It can be printed, including monochrome, two-color and three-color, and can also print the trademark logo and the name of the enterprise, so as to play the role of forging and enhancing the visibility of the enterprise.

3. With high transparency, good gloss, high adhesion, smooth sealing, light quality, and non-toxic, odorless, safe, performance price is good.

4. The comprehensive performance is better than moisture-proof cellophane, polyethylene (PE) film, PET film.

Four, the choice of BOPP tape

1. The choice of tape

There are many kinds of tape, and there are many kinds of adhesive on the surface, so the performance and strength of various brands of tape are different, so the following factors need to be considered when purchasing tape:

(1) Microporous adhesive: Due to the adhesive tape action, the adhesive water on the surface of the adhesive tape seeps into the adhesive after the adhesive tape is glued and dries quickly, making the adhesive tape become a part of the adhesive tape. Therefore, the microporous adhesive surface is very important for the selection of adhesive tape. If the microporous or hygroscopic force is larger, it is necessary to use adhesive tape with rapid condensation, otherwise, use adhesive tape with slower condensation speed or tape with more adhesive.

(2) Initial adhesion strength and holding force: there are two standards for the glue quality of adhesive tape in use, one is the initial viscosity force, one is the holding force, the two are inversely proportional. Under normal circumstances, adhesive tape is less than 10 glue coating, generally only about 20 microns, such as stationery tape, ordinary promotional binding tape; The initial adhesive thickness of normal sealing tape is generally 22-48 microns.

2. The choice of colored tape

Generally yellow and earth yellow more. Pinch the adhesive tightly and then quickly pull it apart, you can pull the glue off one side, you can see the purity and transparency of the original film, you can also see the thickness of the glue. If no glue is pulled apart or pulled apart punctually, there are a lot of impurities in the glue, and the glue has no cohesion; Two is too much water, has volatilized. At this time, the initial adhesive force of this tape has fallen very badly, feel can be distinguished.

Leave a Reply

Want to join the discussion?Feel free to contribute!