Background of the invention of acrylic pressure sensitive adhesive

For example, for vehicles such as cars, trains, buses, etc.; Household appliances such as televisions, personal computers, air conditioners, and so on; Office appliances such as fax, photocopier, etc. In airplanes; Boats and ships; houses; Pressure-sensitive adhesives and pressure-sensitive tapes in various fields such as factories, polyvinyl chloride (hereinafter referred to as PVC) are widely used as adhesives or substrates. But the incineration of polyvinyl chloride produces toxic gases such as dioxins and chlorine.

In view of the increased environmental awareness in recent years, restrictions on the use of PVC and a shift to materials that reduce the environmental burden have been initiated. Therefore, there is a strong demand for alternatives to PVC. Similarly, alternatives to the following substances are also needed: pressure-sensitive adhesives containing halogen atoms, and pressure-sensitive tapes containing halogen atoms as substrates as alternatives to halogen atoms containing materials such as PVC. Olefin polymers such as polyethylene, polypropylene, etc., are increasingly being used because of their cost and elasticity. The adhesive body may consider using pressure-sensitive tape with this material as the base material, and pressure-sensitive adhesive and pressure-sensitive tape products use these materials.

When such olefin polymers are used as substrates or adhesives for tape, rubber, and acrylic pressure-sensitive adhesives are used for cost reasons.

However, when rubber pressure-sensitive adhesives are used, the bonding strength for substrates or adhesives made from alene polymers becomes too strong, which can cause problems for pressure-sensitive tapes, such as difficulty unwinding the tape, etc. During unwinding, straps often suffer from substrate stretching, substrate breaking, and so on. When rubber pressure-sensitive adhesives are used in adhesives made from olefin polymers, the cause of the problem is the excessive bonding strength, which can be demonstrated by the residue (i.e., the residue of the adhesive) attached to the adhesive at the time of spallation, etc.

When acrylic pressure-sensitive adhesives are selected, problems such as weak bond strength for substrate surfaces or poor polar adhesives such as olefin polymers can arise

For example, in the case of adhesive tape, the unwinding force and fastening force of the tape are weak, which does not complete enough winding. In addition, because of the weak adhesion to the substrate, the end of the tape will be defective after winding, and so on

By cross-linking the adhesive to increase cohesion strength and so on, you can prevent the end from peeling off, but at the same time, the bond strength is reduced and the unwinding force becomes weaker

As compensation, consideration has been given to adding viscosifiers to acrylic pressure-sensitive adhesives (e.g., resin viscosities, serene viscosifiers, petroleum aliphatic hydrocarbons (C; Viscosifier, petroleum aromatic (C) viscosities, and its hydrogenated compounds, etc.), trying to increase the bonding strength of the adhesive.

Changsheng is also a company dedicated to the research and development, production and sales of emulsion pressure-sensitive adhesives. We can effectively solve the problems that customers encounter in the use of glue because of different production equipment and technology.

We specialize in the production of the protective film and pressure-sensitive adhesives for many years, with our own R&D team. In the future, through continuous research and development and summing up experience, our glue can be applied to more product application fields.

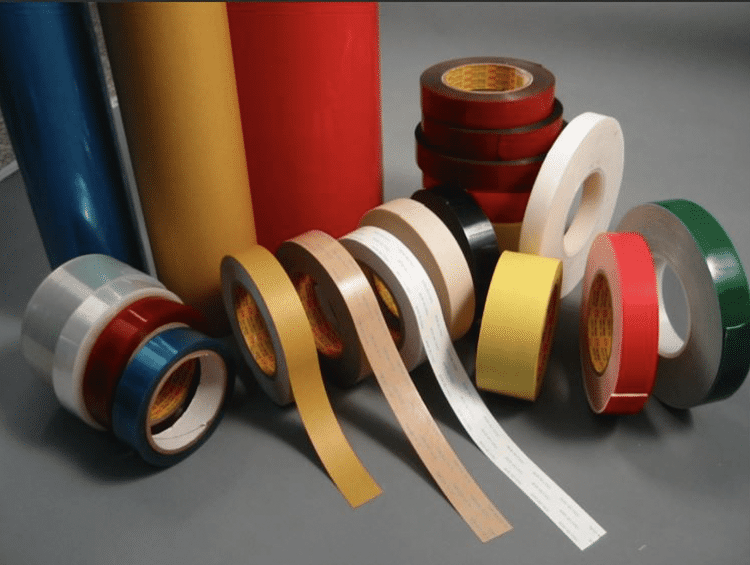

Our acrylic pressure-sensitive adhesive is widely used in:

-

Fit of different film materials

Hot item: Glue FR-201

Advantages: Our laminating adhesive has strong peeling strength, suitable for laminating BOPP, CPP, PET, PE or other lightweight packaging film materials.

-

Protective film for household appliances

Hot stuff: Glue FR-07; Glue FR-102-2

Advantages: The series of adhesive peeling force increase small, does not leave residue, good anti-scalding performance.

The FR-07 is suitable for smooth surfaces of stainless steel, and the FR-102-2 is suitable for slightly rough surfaces.

-

outdoor protective film

Hot stuff: Glue FR-04; Glue FR-W78-1; Glue FR-091-6

Advantages: This series of glue has the advantages of temperature resistance (including high and low temperature), moisture-proof, and waterproof performance. Their adhesive force is different and can meet different bonding requirements.

Glue FR-091-6 is especially suitable for carpets, fluorocarbon spray aluminum profiles, and other rough surface.

-

Off-line Low-E glass protective film

Hot item: FR-08-J7

Strength: It has the characteristics of strong stripping strength and moderate unwinding performance.

Wuxi Changsheng Adhesive Products Co., Ltd. is also committed to emulsion pressure-sensitive adhesive research and development, production, and sales of the company. We can effectively solve the problems that customers encounter in the use of glue because of different production equipment and technology.

We specialize in the production of the protective film and pressure-sensitive adhesives for many years, with our own R&D team. In the future, through continuous research and development and summing up experience, our glue can be applied to more product application fields.

Leave a Reply

Want to join the discussion?Feel free to contribute!