Technical background of pressure-sensitive adhesive tape used to fix the diagram of capacitor components

Wet or dry spiral aluminum electrolytic capacitor color bracket inserted in an electrolyte-containing aluminum box (aluminum c(metal shell) capacitor element, wherein by winding aluminum foil (electrode foil) to obtain the capacitor element, and the aluminum foil has been made of canna-flan electrolytic paper or in its upper pressure on the surface of the isolation, the sheet has been corrupted or oxidized. The outermost layer of the laminated material may be electrode foil or electrolytic paper or isolation sheet.

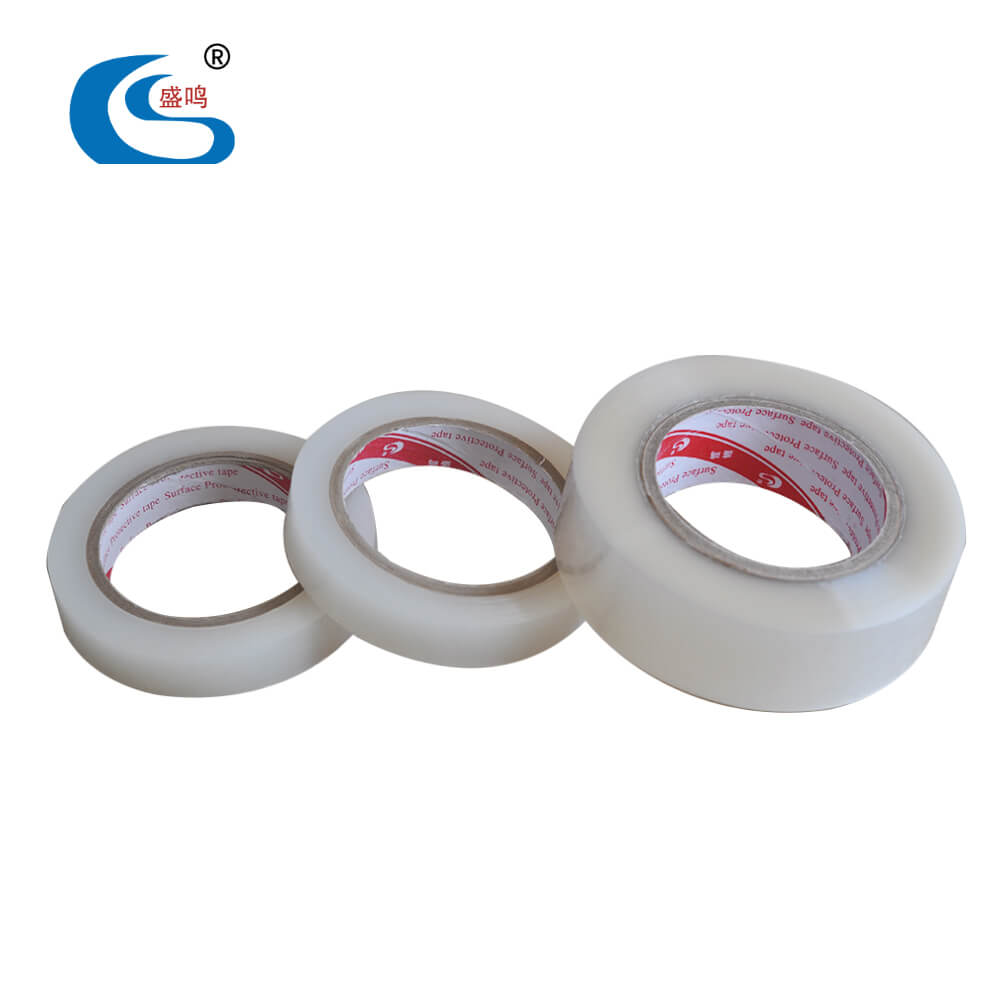

As a method of preventing the line ends of such capacitor components from loosening, a method has been used to date method includes a diagram of the adhesive applied directly to the outermost layer of electrolytic paper or spacer for bonding and securing capacitor elements: Or one method is to glue a pressure-sensitive adhesive tape with a width basically equal to the degree of the capacitor element to the capacitor element around or more places, and make the transverse range of the pressure-sensitive adhesive tape is consistent with the height of the transformer element, such a pressure-sensitive adhesive tape used as a coil to fix the transformer element, The main use of biaxial tensile poly terephthalate PET), polypropylene PP), polyphenylene sulfide (PPS) or similar as support substrate pressure sensitive adhesive tape, or containing unstretched polyimide P or polyimide PED as support substrate pressure sensitive adhesive tape.

On the other hand, electrolytic capacitors are required to have heat resistance. For example, a strong aluminum electrolytic capacitor designed to be used at high temperatures requires a tolerance of 150℃. For substrate components with more surface packaging (installation): it is required that the time be subject to a temperature of not less than 250℃ produced by the flux softener, which has recently been more frequently affected by the increased flux melting temperature due to lead removal. Therefore, it is required to be used in the diagram of the fixed capacitor element

Pressure-sensitive adhesive tape withstands negative self-temperature applied to the capacitor element. In addition, in the dry aluminum electrolytic capacitor in its preparation process, in the electrolytic paper or isolation sheet carbonization step, in the temperature of not less than 250℃ 30 heat treatment, therefore, the dry aluminum electrolytic customer is also required to withstand high temperature. Therefore, it is necessary to provide pressure-sensitive adhesive tape for securing the diagram of the electrical element, which ensures that not only loosening but also a short circuit of the capacitor element is prevented, even at temperatures not below the glass transition point of the resin forming the substrate film.

Leave a Reply

Want to join the discussion?Feel free to contribute!