A pressure-sensitive adhesive consisting of an acrylic polymer grafted with ethylene butene rubber macromolecular monomers

A pressure-sensitive adhesive consisting of an acrylic polymer grafted with ethylene butene rubber macromolecular monomers

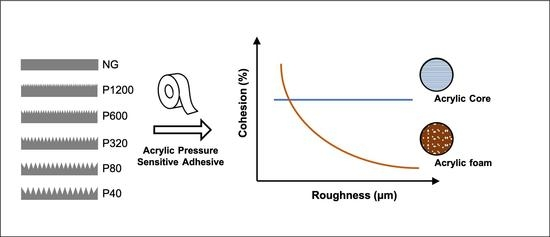

A typical acrylic pressure sensitive binder is a copolymer of an alkyl ester monomer, a functional monomer such as acrylic acid, which can be crosslinked with a chelating agent such as aluminum. These adhesives generally lack adhesion to low-energy surfaces, but these adhesives can be improved by adding rosin esters to lower-energy surfaces. But at the same time lead to the loss of heat resistance and aging resistance. Even at the expense of good aging resistance, viscosified acrylic dispersion is sufficient for some uses, such as most paper labels, and has actually become the dominant paper label technology.

However, these enhanced acrylic adhesives do not have the degradation resistance required for most cartographic and industrial tape applications, where acrylic solutions are commonly used. Rubber resin compositions are often used to bond polyolefin and other low-energy substrates. Typical compositions are rosin ester-reinforced natural rubber or styrene block copolymers. These compositions have excellent adhesion and bond strength, but the degradation caused by oxidation and ultraviolet irradiation will fade and lose viscosity. A fully hydrogenated rubber and resin composition, in addition to the added cost, does not have the required bonding properties. The United States patent has been published for a hybrid rubber acrylic pressure sensitive adhesive with excellent UV resistance and aging properties while having excellent adhesion to non-polar surfaces.

Despite these advances in the field, there is still a need to improve polymer compositions used to prepare pressure sensitive adhesives in areas such as industrial tape, transfer films, and exterior graphics that require sufficient adhesion and chemical resistance to work with low-energy difficult-to-bond surfaces.

Leave a Reply

Want to join the discussion?Feel free to contribute!