Industry share: Preparation method of acrylic pressure sensitive tape with high temperature resistance mesh 3

Preparation method of acrylic pressure sensitive tape with high-temperature resistance mesh 3

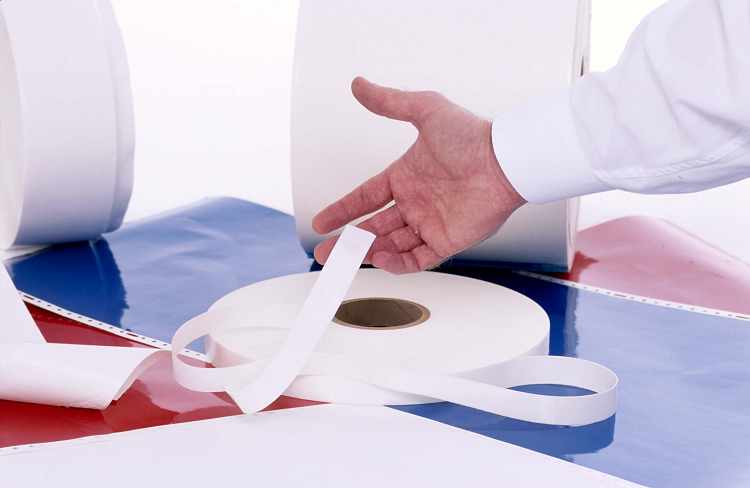

The utility model relates to a high-temperature resistant mesh acrylic pressure sensitive tape, which comprises a mesh release film and a modified acrylic pressure sensitive adhesive coated on the surface of the mesh release film. Wherein, the composition of the modified acrylic pressure sensitive adhesive is calculated by weight, including 30 butyl acrylate, acrylic 2 ethyl caproic ester 24, 2 hydroxyl ethyl acrylate 20, 8 aniline propyl cage half as many poly siloxanes 8. 8 of tungsten, acrylic amide acid scandium powder 5. 6, initiator 3. 6, the first solvent 12 and 24-second solvent.

Wherein, the mesh release film is a PET material release film; The first solvent and the second solvent composition are the same, which is ethyl acetate; The initiator is dibenzoyl peroxide.

Among them, the preparation method of the acrylamide scandium tungstate powder is:

S1. Preparation of amino-modified scandium tungstate powder: Acid scandium tungsten powder and the mass fraction of 50% hydrogen peroxide solution mixed, evenly spread, and heat to boiling Teng, reflux condensation mixing 8 12 h, after natural cooling, vacuum suction filter out of solid particles, water three times, then vacuum drying, hydroxy modified tungsten acid scandium powder; Among them, the weight ratio of scandium tungstate powder to hydrogen peroxide solution is 1:20; The hydroxy-modified scandium tungstate powder was mixed with 70% ethanol aqueous solution, dispersed evenly, and the amino silane coupling agent KH792 was added. After stirring at 25℃ for 12h, the temperature was raised to boiling, and reflux condensation was stirred for 7h.

After natural cooling, the solid particles were filtered out by vacuum, washed three times, and then dried by vacuum. Amino-modified scandium tungstate powder was obtained. Among them, the weight ratio of hydroxy-modified scandium tungstate powder, amino silane coupling agent KH792 and ethanol aqueous solution is 1:0.12:12;

S2. Preparation of scandium acrylamide tungstate: the amino-modified scandium tungstate powder is dispersed in tetrahydrofuran solvent, constantly stirring until uniform, then heating up to 50℃, drop by drop add acrylic anhydride, under the condition of shade, heat insulation stirring for 20h, decompress to remove the unreacted acrylic anhydride and tetrahydrofuran solvent, scandium acrylamide tungstate powder; Among them, the weight ratio of amino-modified scandium tungstate powder, acrylic anhydride, and tetrahydrofuran solvent is 1:5.2:20.

The preparation method of the above high-temperature resistant mesh acrylic pressure sensitive tape includes the following steps:

Step 1: Prepare complex modified scandium tungstate mixture: The powder of scandium acrylamide tungstate was dispersed in the first solvent, and octal aniline propyl cage polysesquisiloxane was added, ultrasonic uniformity, and then mixed at 25℃ at the speed of 1200r/m for 20h to obtain the complex modified scandium tungstate mixture.

Step 2: Prepare modified acrylic pressure sensitive adhesive: Butyl acrylate and acrylic acid 2 ethyl caproic ester, ethyl 2 hydroxyl acrylic mixed into the second solvent, stir to dissolve, straight ventilation with nitrogen gas as shielding gas, with half of the initiator, temperature to 70 ℃, stir at a speed of 200 r/m after 1 h, adding the other half of the initiator, At the same time, the compound modified scandium tungstate mixture was added drop by drop within 30min, and then the temperature was raised to 75℃, and the temperature was kept and stirred at the speed of 300r/m for 6h. After the reaction, the modified acrylic pressure sensitive adhesive was obtained by natural cooling.

Step 3: Prepare high-temperature resistant mesh acrylic pressure sensitive tape: cut the mesh release film and lay it on a flat surface, and use the machine to coat the modified acrylic adhesive on the top, and dry it in the oven at 120 ℃ for 5min to obtain high-temperature resistant mesh acrylic pressure sensitive tape.

Leave a Reply

Want to join the discussion?Feel free to contribute!