Industry share: Preparation method of a water-based polyacrylate block copolymer pressure sensitive adhesive 2

Preparation method of a water-based polyacrylate block copolymer pressure sensitive adhesive 2

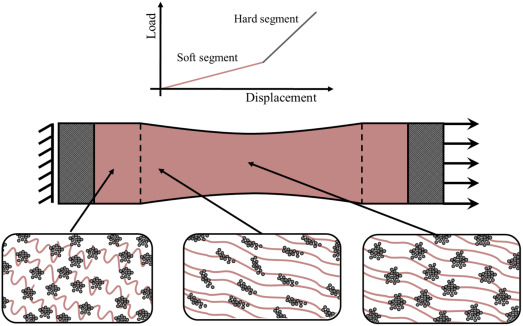

In this embodiment, the water-based polyacrylate block copolymer pressure sensitive adhesive, the pressure sensitive adhesive solid content of 60% is a water-based polyacrylate block copolymer, water-based polyacrylate block copolymer multi-block structure, including hard monomer: isobornyl acrylate 10kg, methyl methacrylate 12kg; Soft monomer: butyl acrylate 50kg, isooctyl acrylate 25kg; Functional monomer: hydroxyethyl methacrylate 1.5kg; Crosslinking monomer, N hydroxymethyl acrylamide 1. 5 kg.

The preparation method of the above water-based polyacrylate block copolymer pressure sensitive adhesive includes the following steps:

S1, 0.8kg sodium dodecyl sulfate was dissolved in 66.67kg deionized water to obtain the aqueous phase, 0.08kg hexadecyl alcohol and 0.08kg trithiocarbonate (Z group is phenyl, the R group is nitrile-isopropyl) were dissolved in the soft monomer successively and added to the aqueous phase. After mixing evenly, the pH of the mixture was adjusted to 10. Then the mixture was dispersed ultrasonically for 20min to obtain the soft monomer pre-emulsification solution.

S2, add the soft monomer pre-emulsion into the reaction kettle, add 0.12kg dibenzoyl peroxide, stir evenly, and heat the reaction solution to 75℃ for polymerization reaction;

S3, after polymerization for 2 hours, hard monomers, functional monomers, and crosslinked monomers were added, stirred evenly and block copolymerization was initiated at 75℃. For S4, after copolymerization for 2h, 0.03kg azodicyanopentonic acid was added and kept at 80℃ for 2h before discharge, to obtain water-based polyacrylate block copolymer pressure sensitive adhesive. When using, the pressure sensitive adhesive emulsion is directly coated on the PET base film of 50μm, the thickness of the dry adhesive is 10μm, and the PET base film is placed in the oven at 125℃ for 3min.

Leave a Reply

Want to join the discussion?Feel free to contribute!